Enhance Your Additive Manufacturing with Artec 3D Scanners

The Role of High-Accuracy 3D Models in Additive Manufacturing

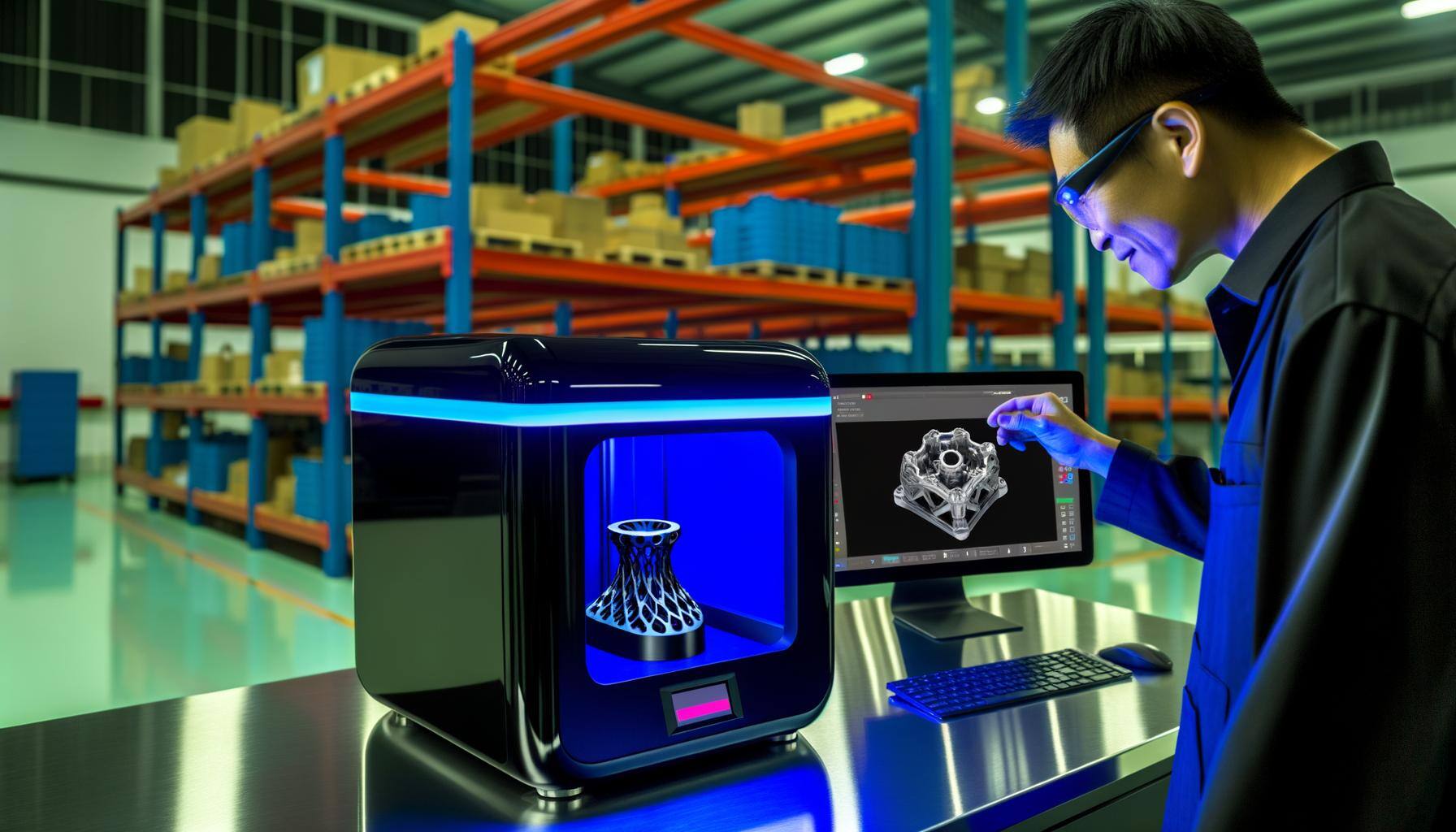

In the world of additive manufacturing, precision is paramount. High-accuracy 3D models serve as the foundation for creating complex, high-quality components that meet stringent performance standards. Artec 3D scanners deliver this precision effortlessly, capturing intricate details with remarkable accuracy. Whether you're crafting flight-worthy aerospace components or custom-designed medical devices, the quality of your 3D models directly influences the success of your final product.

Artec 3D scanners excel in producing detailed, high-resolution models that are essential for additive manufacturing. These models ensure that every layer of your printed object aligns perfectly with the design, reducing the likelihood of errors and enhancing the overall quality. By using Artec 3D scanners, you can achieve superior accuracy and precision, setting a solid foundation for your manufacturing processes.

Reducing Time and Costs with Artec 3D Scanners

Efficiency and cost-effectiveness are crucial in today's competitive market. Artec 3D scanners are designed to streamline your additive manufacturing workflow, significantly cutting down on both time and expenses. Traditional methods of capturing object data can be time-consuming and costly. Artec 3D scanners, however, can capture up to 35 million points per second, drastically reducing the time required for data acquisition.

Moreover, these scanners eliminate the need for contact with the object, allowing you to capture sensitive or fragile items without risk of damage. The user-friendly interface and intuitive design mean that you can get up to speed with scanning in under two hours, minimizing downtime and maximizing productivity. By integrating Artec 3D scanners into your workflow, you can achieve faster turnaround times and reduce labour costs, giving you a competitive edge.

Ensuring Quality Control in Additive Manufacturing

Quality control is a critical aspect of any manufacturing process, and additive manufacturing is no exception. Artec 3D scanners provide unparalleled accuracy, making them ideal for inspection and quality control tasks. By quickly scanning your 3D-printed objects, you can generate high-resolution models that allow for detailed comparison with your original designs.

This capability ensures that any deviations or defects are identified early, preventing costly mistakes and ensuring that your final products meet the highest standards. Additionally, Artec's software solutions integrate seamlessly with industry-standard CAD and CAM programs, providing a comprehensive toolkit for managing and optimizing your quality control processes. With Artec 3D scanners, maintaining impeccable quality control has never been easier.

Applications of Artec 3D Scanners Across Different Industries

Artec 3D scanners are versatile tools used across a wide range of industries. In the automotive sector, they facilitate the creation of custom parts and the reverse engineering of existing components. In healthcare, they enable the production of precise medical devices and prosthetics tailored to individual patient needs. The manufacturing industry benefits from their use in quality inspection and prototyping, ensuring that products meet rigorous standards before they go to market.

The versatility of Artec 3D scanners also extends to fields such as architecture, heritage preservation, and forensics. These scanners can capture detailed models of historical artifacts, architectural structures, and crime scenes, providing invaluable data for analysis and preservation. No matter the industry, Artec 3D scanners offer innovative solutions that enhance efficiency, accuracy, and overall workflow.

Success Stories: Transformative Impacts of Artec 3D Scanners

The transformative impact of Artec 3D scanners is evident in numerous success stories across various industries. For instance, in the medical field, Artec Eva was used to create a revolutionary 3D-printed prosthesis. The process, from scanning to exporting a complete STL file, took just 30 minutes, demonstrating the scanner's efficiency and precision.

In the entertainment industry, Saturday Night Live utilized Artec Space Spider to create custom facial props for their hosts. This quick and accurate solution replaced traditional lifecasting methods, saving time and enhancing the quality of the props. Similarly, the automotive industry has benefited from Artec 3D scanners, with companies like Ruffian Cars using them to reduce development time for custom auto parts significantly.

These success stories highlight the diverse applications and substantial benefits of integrating Artec 3D scanners into different workflows. The scanners' ability to deliver high-accuracy data quickly and efficiently makes them indispensable tools for modern manufacturing processes.

Choosing the Right Artec 3D Scanner for Your Needs

Selecting the right 3D scanner for your specific needs is crucial to maximizing the benefits of additive manufacturing. Artec offers a range of scanners, each designed to address different challenges and applications. For handheld scanning, the Artec Leo and Artec Eva are excellent choices, offering portability and high accuracy. Artec Leo's wireless functionality and inbuilt touchscreen make it particularly user-friendly, while Artec Eva is renowned for its versatility and speed.

For capturing small objects with intricate details, the Artec Micro II provides metrology-grade accuracy, making it ideal for quality inspection and reverse engineering tasks. On the other hand, the Artec Ray II is perfect for long-range scanning, capable of capturing large objects and scenes with impressive precision from up to 130 metres away.

By understanding your specific requirements and choosing the right Artec 3D scanner, you can enhance your additive manufacturing processes, ensuring high-quality outcomes and optimized workflows.

To explore how Artec 3D scanners can revolutionize your additive manufacturing processes, visit Objex Unlimited. Their expert team can help you find the perfect solution for your needs, ensuring that you achieve the highest standards of precision, efficiency, and quality in your manufacturing endeavours.